|

MEETING # 1584

4:00 P.M.

March 13, 1997

Hoover Dam

by John Templeton

Assembly Room, A. K. Smiley Public

Library

SUMMARY

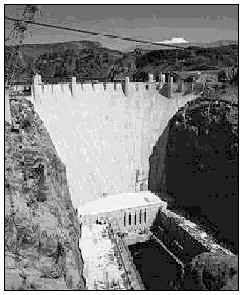

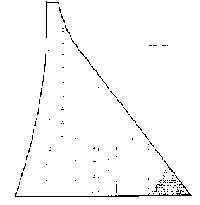

Hoover Dam, the highest concrete arch dam in the United States, 726

feet above bedrock, backs up the waters of the Colorado River 115 miles, forming Lake

Mead. Construction was begun in 1931, and the dam was dedicated September 30, 1935, by

President Roosevelt. Initially called Boulder Dam, the dam was renamed by Congress in 1947

in honor of the 31st president, Herbert Hoover.

HOOVER DAM

Content

Construction Contract

Rail Line

Electric Power

Boulder City

Diversion Tunnels

Aggregate Mining

Concrete Plant

Tunnel Lining

Cofferdam

High Scalers

Riverbed Preparation

Cableways

Concrete Placement

Spillways4

Penstocks

Tunnel Plugs

Dedication

Flood of 1983

Construction Contract

Last October Marge and I visited the Lake Mead Recreation area

expecting to explore Hoover Dam once again. But Rt. 93 was being repaired on the Arizona

side of the Colorado River and the one-lane-at-a-time restriction across the dam crest,

backing up traffic for miles, stopped our quest. Instead we spent time at the visitor

center located about half way between Boulder City and the dam and viewed the 30 minute

film describing the construction process. That was fascinating! Being an engineer, I

wanted to understand the ingenious ways men and machines were used to tame the Colorado as

it roared unchecked through the Black Canyon.

A visitor to Hoover Dam sees the crest and face of a massive

concrete structure, its curved upstream face holding back the huge expanse of Lake Mead,

the four graceful intake towers, and the U-shaped power house just above river level at

the downstream face of the dam. If the visitor takes an elevator down through the

interior, he gains some sense of how the river is directed through the intake towers into

huge steel tubes (penstocks), down to turbines and electricity generators in the

powerhouse, before being discharged and allowing a now tamed river to resume its course.

But how was all this accomplished while the river continued its

inexorable march from the high country in the Rockies, along the California-Arizona

border, and finally into Mexico and the Gulf of California--sometimes fairly placid, but

often a raging torrent swollen by spring runoff?

The construction contract (for just under $50 million) was won by "Six Companies", a consortium made up of Utah, Morrison-Knudsen, J.F.Shea,

Pacific Bridge, MacDonald & Kahn, and Bechtel-Kaiser-Warren Brothers. Frank Crowe was

named general superintendent of construction. Listed in the specifications were 119 bid

items: 3.7 million cubic yards of rock were to be excavated, 4.4 million cubic yards of

concrete poured, 45 million pounds of pipe and structural steel put in place, and so on.

The government would provide all the materials entering into the work, such as cement and

steel, but it was up to the contractor to furnish all the machinery, tools, vehicles, and

supplies needed to carry out construction. The job was to be finished in seven years,

Deadlines were set for various phases of the work and a schedule of penalties was fixed

for any delays.

Rail Line

Before work could begin in the canyon, Las Vegas and Black Canyon

had to be linked by rail. The laying of the first ties and rails offered an ideal

opportunity for celebrating the project's startup, and Nevada Governor Fred Balzar and

Interior Secretary Wilbur decided to capitalize on it. September 17, 1930 was selected as

the date. For Wilbur the event was to prove especially memorable. First, his pocket was

picked soon after he arrived in Las Vegas, an episode that strengthened his already low

opinion of the town. Then, immaculately dressed in three-piece suit, starched collar, and

wingtips, Wilbur was obliged to drive a spike of Nevada silver into a railroad tie with a

phalanx of eager photographers poised to record every miss swing. He concluded his short

speech saying "I have the honor to name this greatest project of all timeľ the Hoover Dam." The anti-Hoover press

blasted him for his "ignorance' and "unapproachable gall," characterized

him as "a consummate ass" for changing the dam's name by executive fiat. By

choosing to honor Herbert Hoover, he had touched off a partisan political battle that

would last seventeen years, during which the dam's name would be changed back to Boulder

Dam before it was permanently made Hoover Dam in 1947.

Electric Power

There was a problem of getting enough electricity into the canyon to

operate heavy equipment and light the tunnel interiors. Southern Sierras Power Company was

awarded a contract to construct a 132,000 volt transmission line 222 miles across the

Mojave Desert from San Bernardino and Victorville to a substation on a rocky promontory

near the canyon rim.

According to the original timetable for the Boulder Canyon Project,

Boulder City was to be completed before work in Black Canyon began, but President Hoover's

decision to accelerate the entire job meant that the town would have to be built hastily,

even as other phases of the dam construction, involving hundreds of men with no place to

live other than rough dormitories and shacks along the river, proceeded through the hot

summer months.

Boulder City

By the end of April, 1931, crews of carpenters, plumbers, and

electricians were hard at work knocking together the first buildings to rise on the

Boulder City town site. In June the first of eight large dormitories that would house

unmarried Six Company workers was finished. The dormitories would be home to almost

sixteen hundred men at the height of the Hoover Dam construction. The charge for one of

the cubicles, plus three meals in the mess hall and transportation to and from the dam

site, was set at $1.65 a day, to be deducted from the worker's biweekly paycheck. For a

laborer earning the minimum wage of $4.00 a day, this amounted to more than 40% of his

gross pay; it was a stiff price but one that men who had been living in tents or lean-tos

and scrounging food wherever they could find it generally were happy to pay.

At the highest point in town a large, rambling, Spanish-style

hacienda was built as an executive lodge and guest house. On a knoll west of the lodge,

slightly lower in elevation but with an equally commanding view, another large

Spanish-style house was built for Frank Crowe and his family.

It was some five hundred feet farther down the slope that most of

the Six Company homes were built. These rough three-, two-, and one-room frame cottages

were rented to married laborers. Six hundred thirty of them were erected in about six

months' time, all identical and all ugly.

Of all the operations that would be part of building the largest dam

in the world, diverting the Colorado was the most important and the most difficult. The

riverbed had to be exposed, pumped dry, and excavated down to bedrock so that the dam's

foundation could be securely anchored and the U-shaped powerhouse at its base constructed.

Room also had to be made for men, materials, vehicles, machine shops, and a large concrete

mixing plant on the canyon floor close to the place where the dam would rise. In all,

nearly a mile of riverbed would have to be securely sealed off from the Colorado's waters

for up to four years while the concrete was being poured. It was imperative that the

diversion system be absolutely reliable, even in the face of one of the Colorado's

legendary floods, for a breach could drown the dam site, wipe out millions of dollars'

worth of work, and threaten the lives of hundreds of laborers.

Division Tunnels

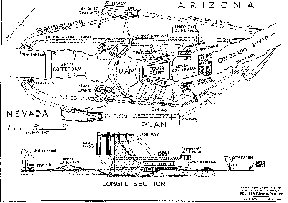

To do this, four enormous diversion tunnels were driven through the

rock walls of Black Canyon; numbers 1 and 2 on the Nevada side of the river, 3 and 4 on

the Arizona side. Work started in the spring of 1931 and was far enough along by November

1932 that water could be directed into the shortest of the four tunnels (3560 feet long)--

#3 on the Arizona side.

The fifty-six foot bore of each tunnel, as wide as a four lane

highway and as tall as a five story building, was too big to drill and blast in a single

operation The enormous tunnel faces had to be separated into sections and each section

excavated separately in a fixed sequence,

The first step was to drive a 12-by-12-foot pioneer heading along

the top of each 56-foot cross section to provide ventilation and access for the

enlargement that would follow. Crowe's scheme provided for the pioneer headings to be

opened off both the Arizona and Nevada edits (horizontal holes bored to intersect the

center of the diversion tunnels) and at the tunnel portals themselves to increase the

number of rock faces available for drilling and blasting. Once these square shafts were

open, the wedge shaped wing sections on either side could be removed. The next step was

excavation of the 30-by-50-foot bench sections, leaving a tunnel 42-feet high, allowing

working headroom for the big electric shovels that would muck out the blasted rock. The

crescent-shaped invert section would be removed last, completing the full 56foot-diameter

bore.

New tactics were developed for rapid, efficient drilling, blasting,

and mucking the tunnels. A mammoth motor-driven rig, referred to as a jumbo, used the

chassis of an International ten-ton truck. This squat drilling contraption, bristling with

lengths of sharp steel and dragging its tangle of lifelines behind it, resembled a

disemboweled porcupine, but its remarkable utility more than made up for its ungainly

appearance. It could be backed into the tunnel and up to the bench face, blocked solidly

into position, connected to the air and water lines, and have its drills pointed and ready

to go in twenty minutes or less. After the left side of the bench was drilled, the jumbo

simply pulled away and backed up to the right side and the drilling operation was

repeated. Despite its bulk, the machine's contours were such that it could drive down one

side of the tunnel and leave room for a dump truck or an electric shovel to pass on the

other side. It was an ingenious, highly effective piece of equipment that proved to be one

of the keys to beating the deadline for tunnel completion.

Work in the diversion tunnels was fraught with hazards, not the

least of which was getting lost, as Marion Allen discovered not long after he started work

at the dam. the portals were almost identical in appearance, were not well marked and

easily could be mistaken for one another, especially in the dark. lt was an inky-black

night; a stiff northerly wind had swooped into the canyon and was whistling across the

tunnel portals, and the murky surface of the Colorado and the looming face of the Arizona

cliff exuded a damp icy chill. Allen's boss asked him to carry a message to the worker in

charge of the drilling jumbo in tunnel A. Allen took off on the run, heading into what he

thought was the right tunnel He was well inside when he realized that something was very

wrong: he did not hear the roar of the jumbo or the clatter of the drills, just the sound

of his own footsteps echoing off the tunnel walls. In a flash he comprehended what the

deathly silence meant, turned, and sprinted back toward the portal, but it was too late.

The thunder of an explosion enveloped him. He was hurled to the floor by the shock wave

and dust and rock fragments peppered his back. He staggered to his feet and limped out of

the tunnel, ignoring the incredulous stares of miners coming in to check the results of

the blast. Allen finally delivered his message, rode home and collapsed in his bed. Not

until ten years later did he learn that both of his eardrums had been ruptured.

Aggregate Mining

Concrete, the very heart and soul of Hoover Dam, was made by mixing

sand and crushed rock with Portland cement and water. Of the four ingredients, the crushed

rock was the most important because it would make up about three-quarters of the dam's

mass; it had to be of high quality and of a consistent size. After much prospecting, a

decision was made to take the 4.5 million cubic yards of aggregate from a broad alluvial

lens on the Arizona side of the river six miles upstream from the dam site.

Concrete Plant

Like so many of the tasks that were preliminary or incidental to the

main job of erecting the dam, the opening of the gravel pit, the construction of a

screening plant in Hemenway Wash two miles west of the river, and the laying and operation

of the rail link between them were engineering triumphs in their own right.

The precipitous cliffs and riverbanks of Black Canyon made it

difficult to find a place suitable for erecting the main concrete plant. A niche in the

cliffs, three quarters of a mile upstream from the Nevada abutment was leveled and

enlarged with jackhammers and dynamite.

The plant, designated low-mix, provided all the concrete for the

diversion tunnel linings, the powerhouse foundation and two-thirds of the dam. A second

plant on the Nevada rim provided concrete for the final 242 feet of the dam.

Inside the barnlike low-mix, aggregates were carried to storage bins

from which they could be siphoned automatically into large containers called batchers. The

eight batchers--one each for the five classes of aggregate, two for Portland cement, and

one for water--fed predetermined portions of ingredients into revolving drum mixers. The

entire process was automated and could be controlled by a single operator pushing a bank

of buttons.

Tunnel Lining

The specifications required all four diversion tunnels to be lined

with concrete three feet thick, reducing their diameter from fifty-six feet to fifty feet

but ensuring their stability and improving their water-carrying capacity. Concrete

pouring, 400,000 cubic yards of it for the 3.1 miles of tunnel, began in mid-March 1932

and was delivered by trucks that roared back and forth from the upstream portals to the

low-mix plant on the Nevada side of the river. It was mechanically troweled into place by

huge movable forms. The pouring in tunnels No. 3 and No. 4 was pushed with special urgency

for it was through these two bores that the river was to be diverted first and they had to

be lined and ready when the Colorado's water level began to drop in the fall.

The gray-white tubes lengthened rapidly, and the Six Companies

engineering staff was encouraged that the deadline for diverting the river would be met.

They were also heartened by cooperation from an unexpected source: the Colorado. The river

had remained unusually placid during the late spring and early summer months, when it was

normally most rambunctious. Winter snowfall in the Rocky Mountains had been relatively

light, reducing runoff and causing the water level to drop faster than in a typical year.

This earlier-than-usual end to the flood season, combined with speedy progress in lining

the Arizona tunnels, permitted scheduling of the initial diversion attempt for early

November.

On the morning of November 1 6th, 12 days after Herbert Hoover was

swept out of office and Franklin D. Roosevelt became the thirty-second president of the

United States, a hundred idling trucks, their dumpers loaded with broken rock, were lined

up along the road that led to the bridge spanning the river just below the upstream

portals of the diversion tunnels. The smooth, coffee-colored sheet of water slid quietly

past the trestles, flowing at seven thousand cubic feet per second, far below its volume

at flood but still powerful enough to be treacherous.

At 11:30 A.M. everything was finally ready, and the signal was given

to begin the diversion operation. Charges in front of tunnel No. 4 were fired, breaching a

dirt barrier and opening the way for water to enter. At the same time the first truck was

driven out onto the bridge, dumped its load of rock into the water below, and raced back

toward the rim and the muck pile, where an electric shovel refilled the truck. One after

another the rest of the trucks roared onto the bridge, dropped their loads, and roared

away' only to return again a few minutes later with another load.

Hours passed, day shift gave way to swing shift, but still the truck

procession continued unabated, bombarding the river with a fresh avalanche of rock every

fifteen seconds.

In the glare of arc lights illuminating the dumping area the water

level was rising noticeably, straining to stay above the barrier of muck being hurled in

its path. It sluiced over the crest and rushed down the sloping downstream face. Upstream

the black water was inching up the rocky banks and lapping at the dirt barriers in front

of the tunnel portals.

By dawn the top of the diversion dam had broken through the rivers

surface. At 7:30 spectators watched as the water climbed the final barrier, raced down

from the crest and plunged toward the dark tunnel inlet. In an instant the small

enbankment melted under the watery onslaught and the Colorado gave up its struggle to flow

free through its ancestral bed and poured into the smooth concrete channel that had been

laid for it.

To ensure that the hard-won victory of turning the

river out of its old channel was not lost later during the high-water months, work was

begun on two earth-and-rock cofferdams. The upstream structure was particularly important

because it would have to hold back the water that would pool between it and the diversion

tunnel's portals. It would also have to be sturdy enough to withstand the devastating

impact of a Colorado River flash flood; a peak flow of 150,000 cubic feet per second was

possible. To ensure that the hard-won victory of turning the

river out of its old channel was not lost later during the high-water months, work was

begun on two earth-and-rock cofferdams. The upstream structure was particularly important

because it would have to hold back the water that would pool between it and the diversion

tunnel's portals. It would also have to be sturdy enough to withstand the devastating

impact of a Colorado River flash flood; a peak flow of 150,000 cubic feet per second was

possible.

Cofferdam

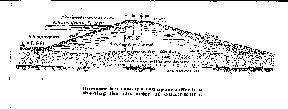

Although it was not necessary for the upper cofferdam's base to be

anchored to bedrock, its footing had to be solid. By the time a firm, compact dirt layer

was struck in early December 1932, over 00,000 cubic yards of river silt had been

excavated.

For a temporary structure the dimensions of the cofferdam were huge: 98 feet

from base to crest, 480 feet from canyon wall to canyon wall and 750 feet wide at the

base. But, given the tremendous power and unpredictability of the Colorado, and the

disaster that would occur if the barrier were breached, they were not at all excessive. For a temporary structure the dimensions of the cofferdam were huge: 98 feet

from base to crest, 480 feet from canyon wall to canyon wall and 750 feet wide at the

base. But, given the tremendous power and unpredictability of the Colorado, and the

disaster that would occur if the barrier were breached, they were not at all excessive.

Dry sand and gravel was carried by train and then trucks from

upstream pits in Hemenway Wash to the cofferdam site. During December as many as four

thousand truckloads of fill were deposited each day on the crest of the swiftly rising

cofferdam, and on New Year's Day 1933, the final few loads were rolled into place. Both

the upstream and downstream faces were blanketed with crushed rock, and the upstream face

was paved with reinforced concrete.

The conclusion of this job well before the onset of the spring flood

season virtually eliminated the possibility that high water would inundate the main

construction area. A smaller cofferdam was built just upstream from the diversion tunnel

outlets to prevent backwash from eddying up into the canyon and interfering with

excavation of the powerhouse foundation. After its use for diversion had been fulfilled,

the lower cofferdam was removed, otherwise it would obstruct the flow from the powerhouse

tailrace.

The diversion works were designed to safely carry the maximum flood

ever recorded in Black Canyon of  200,000 cubic feet per second, but they were only required in the

following years to turn a flow of 70,000. 200,000 cubic feet per second, but they were only required in the

following years to turn a flow of 70,000.

Before excavations for the dam and powerhouse could be started in

the river channel between the two cofferdams, the stripping of loose and projecting rocks

from above the sites of all structures and the cutting of niches in the cliffs for intake

towers, dam abutments, back walls of powerhouse, and canyon war-l outlet works, had to be

completed. The cliffs were scored with crevices and pocked with pits and blisters where

slabs of rock had broken loose and were about to fall. Above the cliffs, the steeply

angled slopes rising to the canyon rims were studded with jutting outcrops of fractured

rock and littered with boulders and unstable scree slides. Besides threatening worker

safety, fissures and scales in the rock where the concrete of the dam met the sides of the

canyon would undermine the stability of the entire structure and permit potentially

disastrous seepage around the arch.

High Scalers

This work, probably the most hazardous and undoubtedly the most

spectacular of all construction proceedings, was performed by "High-scalers",

men of iron nerves and dauntless courage. Ropes were secured to steel rods, inserted in

drilled holes near the crayon rims, and dangled over the sheer cliffs toward the canyon

floor far below. The high-scalers climbed down the ropes and fastened their safety belts

or bosun chairs to the suspended ropes by a special knot. They went over the side weighted

down with wrenches, crowbars, water bags, and other paraphernalia. Once they were in

position, the 44-pound jackhammers and bundles of drill steel were lowered to them; they

tightened the stopper hitches, attached their safety belts, planted their feet against the

wall, leaned backward out over the abyss with only the narrow plank oft he bosun's chair

for support, and began drilling. Here, hour after hour amidst the dust from drilling,

searing heat from black walls, or raw gravel-laden winds of winter, they drilled for

blasting, loaded holes with dynamite, or pried off loose rock, while below lay an

unobstructed fall of hundreds of feet. It is to the great credit of the high scaler's

skill and his observance of safety precautions that only seven men lost their lives in

this dangerous undertaking, although the work was in progress for more than two years and

400 were employed at one time.

Perhaps the worst such incident, judged by the terrifying impression

it made on the men who witnessed it, was the death of high scaler Jack (Salty) Russell in

September 1931. Russell had gone over the Arizona rim at the start of the day shift and

was operating his jackhammer on a ledge far above the river. Workers on the rim began

lowering a sling full of drill steel when, without warning, one of the long, glittering

bars slipped loose and hurled downward. The plummeting missile struck Russell flush on the

head. Without a sound he fell, bouncing like a rag doll off several promontories, four

hundred feet to the river bank. The carnage was dreadful.

The aftermath of this tragic episode was as disturbing as the

accident itself. By law the body of an accident victim could not be removed until the

county coroner had examined it at the scene. Russell's body had landed on the Arizona side

of the Colorado. On this day it took the coroner six hours to travel the sixty-five miles

over a rough desert trace from Kingman, and for almost the entire shift workers had to

pick their way around the blood stained sheets and swarms of buzzing flies.

There was another legal twist to the placement of bodies of men

killed or injured in Black Canyon: the state of Arizona paid more compensation to accident

victims or their survivors than did Nevada. The border, which had beer a 300-foot-wide

river, was now just an imaginary line bisecting the canyon floor. The bodies of men killed

in Nevada were often dragged by their co-workers to the Arizona side of the canyon.

Likewise, men who were injured near the border made every effort to get across before

medical and supervisory personnel arrived on the scene.

Riverbed Preparation

The task of scouring the riverbed began immediately after the

Colorado was diverted in November, 1932. A fleet of electric shovels, draglines,

Caterpillar tractors, and dump trucks, supported by an army of shovel-wielding mockers,

was ready to attack the deep blanket deposited over countless centuries by flowing water.

From the water line staining the cliffs, great fans of sand and slimy gravel extended out

and down over 100 feet to the center of the gorge, where stagnant pools, ringed by

silt-smoothed boulders, traced the outline of what had been the river's main channel.

Every day some twenty-two thousand cubic yards of silt and gravel were hauled out of the

canyon and dumped into railroad cars to be carried upstream for disposal.

In mid-April, 1933, the steel jaws of the dragline buckets struck

bedrock, 40 feet below the river's level. From here the bedrock shelved out from both

canyon walls 150 feet to the middle of the canyon, then dropped sharply to form a V-shaped

channel 75 feet deep. This narrow slot would make an excellent natural keyway for the

dam's base, but first its filling of loose sand and gravel had to be dug out and its

walls, which had been deeply carved and fluted by the whirlpools of the ancient river, had

to be trimmed to create a uniform surface to which concrete could bond.

In early May, Jack Savage, the Bureau of Reclamation's chief design

engineer, made a thorough inspection of the foundation and formally approved the

excavation. With this endorsement, the preparatory phase was over and concrete pouring

could begin. The relatively lucrative tunneling, high scaling, river diversion, and

foundation work had been finished more than a year ahead of schedule, allowing the

contractors to bank substantial profits. But all could still be lost. Crowe had committed

Six Companies to pour 3.4 million cubic yards of concrete for $2.70 per cubic yard, a

price 35% below that quoted by the runner-up and 17% less than the Bureau of Reclamation's

estimate. If he failed to deliver and it proved impossible to pour concrete as quickly and

cheaply as he thought, Six Companies might well lose all the money it had earned so

far.

CablewaysI

In the narrow cul de sac of the dam site, rapid, precise movement of

thousands of men, tons of supplies, and mountains of concrete seemed almost impossible,

but Crowe knew exactly how he was going to do it. He would fill the sky over Black Canyon

with a web of cableways allowing him to pick up anything--a truck, a bucket of concrete, a

crew of carpenters, a single wrench--and lower it in a matter of seconds to any point

within the mile-long construction site.

The heart of this network, put into place in 1932-33, was a skein of

five twenty-ton cableways stretching over the portion of the site that contained the

spillways, intake towers, dam, powerhouse, and outlet works. The steel cables were strung

between ninety-foot towers that moved on railroad tracks. A wheeled carriage, rigged with

fall blocks from which the load was suspended, ran along the cable track. Outhaul and

inhaul cables moved the carriage back and forth across the canyon, the hoist cable lowered

and raised the load, and a dump line released it.

The main operator sat in lonely splendor in a shack perched at the

end of a platform extending thirty feet out over the canyon. By manipulating a bank of

levers, he could pick up an object and send it skimming along the line at twelve hundred

feet per minute, watching or listening for the directions of a signalman who ordered the

cargo to be dropped above its destination, lowered, and released.

Carpenters had been busy hammering together the first of many

hundreds of boxlike wooden forms, and on the morning of June 6, 1933, everything was ready

for the first pour. An eight-cubic-yard cylindrical steel bucket suspended from the steel

cables appeared in the narrow strip of sky eight hundred feet overhead. It hung there

momentarily, then plummeted soundlessly into the canyon, only to be brought up a few feet

short of the slot's shadowy bottom by its steel tether. Two men moved forward, tripped the

bucket's safety latches with their shovels, and leaped back as the bottom dump doors

clanged open, the bucket jerked upward, and a great liquid-gray mass sluiced down onto the

rock. Hoover Dam was on the rise.

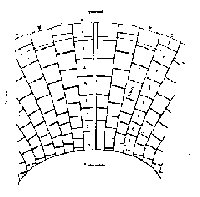

Concrete Placement

Along the stone parapets skirting the Nevada rim, crowds of

onlookers stood for hours gazing down into the abyss, marveling at the gray-white wedge

growing out of its depths. From a distance the dam appeared to grow steadily, evenly, but

it was actually a jumble of concrete boxes rising upward in fits and starts, a horizontal

five-foot-thick layer poured first on one column, then on another. The reason for this

block-by-block approach was the need to dissipate the tremendous chemical heat generated

by the setting concrete. If the dam were fashioned in a single, continuous pour, its

internal temperature would rise forty degrees while it was hardening, it would take 125

years to cool, and the stresses created by the setting process would fracture its body so

severely that it would be rendered useless.

The answer was to pour in individual blocks no more than five feet

thick, and to honeycomb those blocks with one-inch-diameter pipes through which cool river

water and then refrigerated water could be pumped. Thermometers buried in the concrete

monitored the rate of cooling and kept internal temperatures consistent from column to

column. Once the blocks were cool and had stopped shrinking, grout was pumped into the

network of pipes to make each unit solid. Grout was also forced into the joints between

adjacent blocks and into the joints between the concrete and the canyon walls.

Spillways

To prevent a flood from spilling over the dam's crest when the

reservoir was full, spillways 650 feet long and 170 feet deep were cut into the canyon

wails behind the Arizona and Nevada dam abutments. Should the water level rise

dangerously, steel drum gates could be opened, allowing the runoff to pour into concrete

paved channels, plunge 500 feet downward through inclined spillway tunnels that join the

two outer diversion tunnels, and emerge in the river channel below the dam and powerhouse.

Twice the maximum flow of water passing Black Canyon, or 400,000

cubic feet per second could be passed by the spillways. Concrete plugs, 400 feet long,

were placed in the diversion tunnels immediately upstream from the intersection with the

inclined shafts. Slide gates were installed in the Nevada plug to allow controlled water

flow for downstream irrigation while the penstock system and outlet works were being

constructed.

Penstocks

Water for the production of electrical energy, supplying of

downstream requirements and regulation of the reservoir, flows through the gates of intake

towers, then through penstocks to the turbines of the power plant. The four towers that

rise in the reservoir immediately upstream from the dam are graceful concrete spires

resembling huge fluted columns and have all the appearance of monuments rather than

working structures.

Like almost everything else at Hoover Dam, the piping was huge, some

of it thirty feet in diameter. There was not a truck nor railroad flatcar in the country

big enough to haul such a load. So the contractor, Babcock & Wilcox, built a complete

steel-fabrication plant at the dam site, shipping all the necessary machinery--including a

furnace, a vertical rolling mill, and X-ray gear for checking welds--across the country

from Barberton, Ohio. By the spring of 1933 more than 100 employees began to transform

44,000 tons of steel plate into sections of pipe. The next problem was how to get the

monstrous pieces from the plant to the canyon rim and then down 600 feet to the tunnels.

Six Companies designed a tractor-drawn trailer that could carry the 170-ton sections along

the one and a half miles of winding road between the mill and the cliff edge. The huge

government cableway, the largest ever rigged, was strong enough to lower penstock sections

and the turbines for the powerhouse. It became a permanent part of the Hoover Dam complex.

in July 1934, Boulder Canyon Project employment reached its peak

with 5,251 men engaged in some form of construction-related activity. Concrete pouring

continued at a rapid clip, pushing the job farther and farther ahead of schedule. In

January, 1934 a sign hanging from a bucket announced that it contained the one millionth

cubic yard to be put in the dam. Less than three months later the photographer was back,

this time to memorialize the record daily pour of 10,350 cubic yards. In June he was back

yet again to record the placement of the two millionth cubic yard of concrete. The dam was

now nearly two-thirds complete, and it looked less like an uneven hodgepodge of individual

towers and more like a solid, finished structure.

Work on other parts of the dam complex was moving ahead rapidly

also. The lining of the inclined spillway tunnels was finished in March, 1934, and

erection of the drum gates that would control water flow into them began. The intake

towers were approaching their final height of 395 feet. The powerhouse foundation had been

excavated and placement of structural steel and pouring of concrete were under way.

In February, 1935, a concrete bucket was lowered to a shallow form

on column K and the block was topped out, the first to be brought to the dam's final

height of 726 feet. Five more columns were nearly finished, needing only a two-foot pour

to complete the roadway that would run along the dam's crest.

Tunnelplugs

For more than two years the Colorado had flowed through the

diversion tunnels, forced from its ancestral course but still rolling unimpeded toward the

sea. As the low water season began in the fall of 1934, cofferdams were mounded in front

of the portals of the inner tunnels, Nos. 2 and 3, and concrete plugs were dovetailed into

the fifty-foot bores, sealing them permanently. Next, another temporary cofferdam was

erected in front of tunnel No. 1, forcing the river to use No.4, the outer tunnel on the

Arizona side, as its sole route downstream. When the interior of No. 1 was dry, the third

concrete plug was poured, this one perforated with four six-foot-diameter holes, each

fitted with a valve that could be opened or closed on command. January 31, 1935, was the

Colorado's last day of freedom; a steel bulkhead gate weighing more than one thousand tons

was lowered, closing the portal of tunnel No. 4 and forcing the river into No. 1 and

through the honeycombed plug. By manipulating the four valves, water sufficient to meet

the irrigation needs of Imperial Valley was allowed to pass through while the remainder

began to pool behind the dam, forming a lake that would eventually cover 210 square miles.

Dedication

Early on the morning of September 30, 1935, the normally sleepy

downtown blocks of Boulder City were abuzz with activity. Before the day was over, twelve

thousand people would line the cliffs, cover the abutment area, and spill onto the dam's

crest. The event was the dedication of Hoover Dam, the official culmination of four and a

half years of prodigious labor.

At 9:30 A.M., at the Union Pacific Station in Las Vegas, the doors

of a private railroad car opened and the president of the United States was helped to the

platform and then into an open touring automobile. Shortly after 10:30 the motorcade

arrived at the dam, slowly crossed the crest into Arizona and then came back to the

speaker's platform on the Nevada side. The dais was crowded with an impressive array of

officials: Harry Hopkins and Harold Ickes; key Bureau of Reclamation men; Senators Pittman

and McCarran; governors of the six Colorado Basin states; and the heads of Six Companies.

"Gee, this is magnificent," the president exclaimed with a

broad smile as he was seated, and then Harold Ickes stepped forward to deliver the first

address. Key Pittman followed Ickes, and then it was the president's turn to speak.

F.D.R., his dark doublebreasted suit buttoned in spite of the ninety-degree heat, put down

the pages of his speech, gripped the edges of the podium, and looked out at the upturned

faces of the crowd. "This morning, I came, I saw, and I was conquered as everyone

will be who sees for the first time this great feat of mankind" he ad-libbed

The president's voice rose as he began his peroration. "This is

an engineering victory of the first order--another great achievement of American

resourcefulness, skill, and determination." The pitch of his voice fell, and his

words were measured and sincere. "That is why I have the right once more to

congratulate you who have created Boulder Dam and on behalf of the nation to say to you,

'Well done."'

The dam has changed very little since the day it was dedicated. The

concrete in its body is still slowly curing, growing stronger with each passing year.

Alterations have been made in the powerhouse: four generators were

installed during World War II, three more in 1952, and one in 1961, completing the power

plant and bringing the dam's generating capacity to about 1,350,000 kilowatts. In the

early 1980s a program to uprate the plant was begun; as part of this program the original

cast-steel turbine runners were replaced with more efficient, lower-maintenance stainless

steel runners, and new thinner insulation was installed in the generators, increasing

their capacity to more than 2 million kilowatts.

Flood of 1983

Diversion tunnel repairs and modifications were made necessary by

the most dramatic event in the dam's working life: the flood of 1983. It began in late

spring when snowstorms in the Rocky Mountains were followed by a heat wave and heavy

rains. Runoff between April and July was 210 percent of normal, and the Colorado River

reservoirs filled rapidly. On June 6, 1983, Lake Powell behind Glen Canyon Dam was full,

and emergency water releases began through its spillways. By late June ninety thousand

cubic feet of water per second was rushing through the Grand Canyon toward Lake Mead, and

it was apparent that Hoover Dam's flood control capacity would be put to a severe test.

Late in the evening of July 2, the dam's giant steel drum gates were

lifted and a foaming wave crashed into the spillway channels and was sucked into the

diversion tunnels. A cloud of mist rose into the hot desert night, and after a hiatus of

fifty-two years, the wild freight-train roar of the Colorado River was heard again in

Black Canyon.

The flood crested on July 24 when more than fifty thousand cubic

feet of water per second was discharged through the diversion tunnels; the spill was

continued until September 6, when the drum gates were closed. Millions of dollars'

worth of damage occurred in the river corridor downstream from Hoover Dam, but the

destruction was only a fraction of what it would have been if Lake Mead had not cut the

peak from the flood.

The flood of 1983 demonstrated the fundamental soundness of Hoover

Dam's design and the high quality of its construction. Frank Crowe and his work crews not

only built fast, they built well; with proper maintenance the dam's life should be

indefinite.

Bibliography

"Man The Builder" by Gosta E. Sandstrom, McGraw-Hill Book

Company, 1970 "Construction of Hoover Dam", Department of the Interior,

Bureau of Reclamation, Twenty-eighth Edition, 1976 KC Publications

"Hoover Dam An American Adventure", by Joseph E. Stevens,

University of Oklahoma Press, 1988

"The Story of the Hoover Dam", Nevada Publications,

1931-1935 by Compressed Air Magazine

|